Company news

In June 2021, the company undertook the production task of China offshore equipment "Fuyao" offshore floating wind power platform of Guangzhou Wenchuan Heavy Industry Co., Ltd. The platform has a total length of 71.96 meters, a mould depth of 32 meters, a breadth of 80 meters, a design draft of 18.0 meters and a design drainage of about 15600 tons. Compared with the fixed offshore wind power foundation, the floating wind power platform foundation of "Fuyao" has the characteristics of large volume, heavy weight and complex internal structure, with high manufacturing difficulty and strictquality inspection requirements.

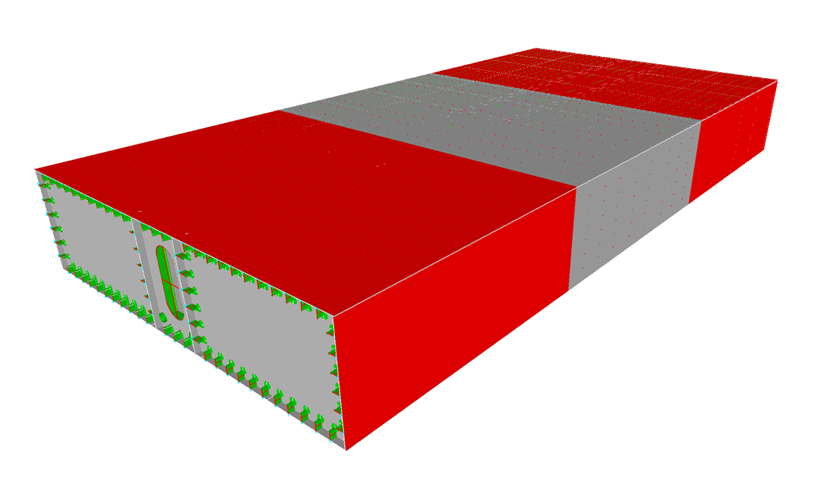

The "Fuyao" floating wind power platform adopts the configuration of three column stabilized platform, which is composed of column, heave plate, lower floating body and upper cross brace, and is in an equilateral triangle layout. The column, lower floating body and cross brace are produced by our company.

Due to the heavy weight of the column section, which exceeds the lifting capacity of the crane in the workshop, the division of small sections increases the difficulty of subsequent closure. After the technical research of the process team, the overall manufacturing method is adopted, that is, a tooling platform is specially made in the workshop, and the bottom of the tooling platform is transported by the module truck. After the column section is manufactured on the tooling platform , the platform and the section are transported out of the workshop with the module truck, It not only solves the limitation of workshop crane capacity, but also improves the construction efficiency.

The lower floating body section and cross brace section are square, with large overall size and long length. In order to overcome the difficulties of component welding and high requirements for closure accuracy, after on-site technical research, the segmented sheet reverse construction method and segmented overall construction method are finally adopted.

Segmented sheet reverse manufacturing method: in order to reduce overhead welding of components, optimize welding operation conditions, ensure welding quality and improve welding efficiency, segmented sheet reverse manufacturing method is adopted. Reverse the welding work at the top for horizontal welding, and then turn over the upper part for bottom welding to realize that most of the top welding work is converted to horizontal welding, so as to avoid overhead welding, reduce the difficulty of welding and reduce the workload of scaffold erection. Sectional overall construction method: multiple sections are built in the workshop as a whole. After the welding of a single section is completed, it is transported to the outfield for overall closure, so as to ensure that the profile of the closure interface of the general assembly is consistent, avoid misalignment and greatly shorten the production period.

Composition diagram of lower floating body

The "Fuyao"

From the end of June to early November 2021, Zhongshan base overcame difficulties and successfully completed the manufacturing task of Fuyao in nearly five months.

The production and manufacturing task of floating wind power platform is the first time in Zhongshan base for the whole company. The previous fixed welding methods and production management experience of offshore wind power steel structure foundation cannot be copied onto "Fuyao". The company faces great tests in terms of welding workload, welding process technology, welder operation level, on-site quality control and production management. Zhongshan base is united to study the relevant technical data of the platform, Welding process guidance and on-site quality control and have overcome the production difficulties of floating platform and successfully completed the project manufacturing task.

The successful manufacture and smooth delivery of the "Fuyao" floating wind power platform indicates that the company has made a new breakthrough in the production and manufacture of the floating wind power platform, and also means that the company's offshore wind power products have moved to a new level in the deep sea and far-reaching offshore field.